Laser processing has become one of the most reliable and efficient technologies in modern manufacturing. From cutting and welding to engraving and marking, laser systems offer unmatched precision, speed, and repeatability. As industries evolve, businesses need a trusted partner who can provide advanced laser solutions that improve productivity and deliver long-term value. This article explains how the right laser partner enhances operations, ensures consistent quality, and supports growth in today’s competitive industrial landscape.

Understanding Laser Processing Technology

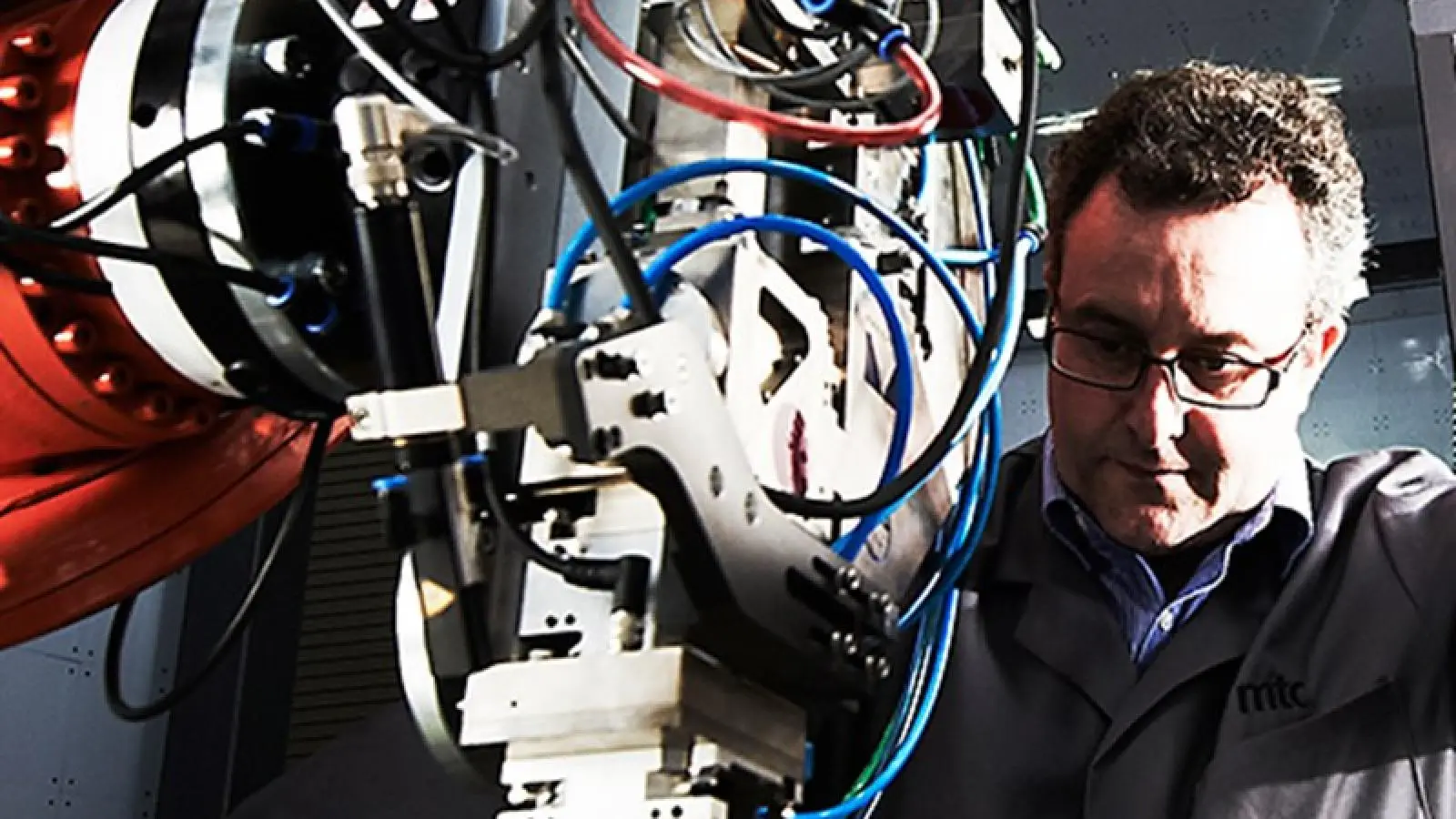

Laser processing involves using a highly concentrated beam of light to cut, weld, engrave, or modify materials. This beam is controlled with extreme accuracy, enabling manufacturers to achieve precise results in a wide range of applications. Industries such as automotive, electronics, aerospace, packaging, and medical manufacturing depend heavily on laser technology due to its consistent performance and versatility.

Key Advantages of Modern Laser Processing

- High precision ensures smooth and accurate results even in complex geometries.

- Minimal material waste due to clean, focused energy delivery.

- Non-contact processing reduces wear and tear on tools.

- High speed and efficiency improve overall output.

- Consistency and repeatability guarantee uniform production quality.

Why You Need a Reliable Laser Processing Partner

Choosing the right partner in laser processing is essential for maintaining productivity and staying ahead of competitors. Your partner should provide more than just equipment; they must be a source of expertise, innovation, and technical support.

Expertise and Guidance

A knowledgeable partner helps you choose the correct laser source, power range, and processing system for your specific applications. Their expertise ensures that your investment is optimized for maximum performance.

Reliable Technology

High-quality laser sources reduce downtime, ensure stable operation, and deliver consistently accurate results. A trusted partner always provides reliable equipment built to withstand demanding industrial conditions.

Custom Solutions

Every industry has unique requirements. Your partner should offer custom laser solutions that match your operational needs, material types, and production goals.

Ongoing Technical Support

Technical issues can slow down production. A dependable partner provides fast support, training, and maintenance services to keep your systems running at peak performance.

Applications That Benefit from Professional Laser Processing

Laser technology is widely used across multiple sectors. Here are a few major applications:

Laser Cutting

Laser cutting provides clean edges, high accuracy, and fast processing speeds. It is ideal for metals, plastics, textiles, ceramics, and composite materials.

Laser Welding

Laser welding enables strong, precise, and clean welds with minimal distortion. It is commonly used in automotive components, electronics assemblies, and custom metal fabrication.

Laser Marking and Engraving

Laser marking produces permanent, high-contrast marks for logos, barcodes, serial numbers, and product identification. It works on metals, plastics, and other materials.

Surface Treatment

Laser surface modification improves hardness, texture, or adhesion by precisely heating and altering material surfaces.

Benefits of Partnering with a Complete Laser Processing Provider

A professional laser partner offers more than equipment. Their services are designed to enhance efficiency, reduce costs, and improve overall performance.

Improved Productivity

With advanced laser systems and automation-ready solutions, businesses can achieve faster cycle times and higher output.

Cost Efficiency

Laser technology reduces scrap, minimizes rework, and lowers operational expenses through energy-efficient systems and long-lasting components.

Enhanced Product Quality

Precision and consistency ensure high-quality results with every cycle, helping businesses meet international standards and customer expectations.

Upgrade and Expansion Support

A committed partner helps you scale your operations, integrate new technologies, and adopt future-ready laser solutions as your business grows.

Choosing the Right Partner for Laser Processing

When selecting a laser processing partner, consider the following:

- Proven industry experience

- Wide range of laser technologies

- Custom solution capabilities

- Strong after-sales support

- Availability of spare parts and upgrades

- Training and technical guidance

A reliable partner focuses on long-term collaboration, helping you achieve operational excellence and remain competitive in a dynamic market.

Conclusion

Laser technology has transformed manufacturing with its precision, speed, and versatility. Choosing the right partner in laser processing ensures you leverage this power to its fullest potential. From expert consultation to reliable equipment and ongoing support, the ideal partner helps your business achieve outstanding quality, improved productivity, and long-term success.